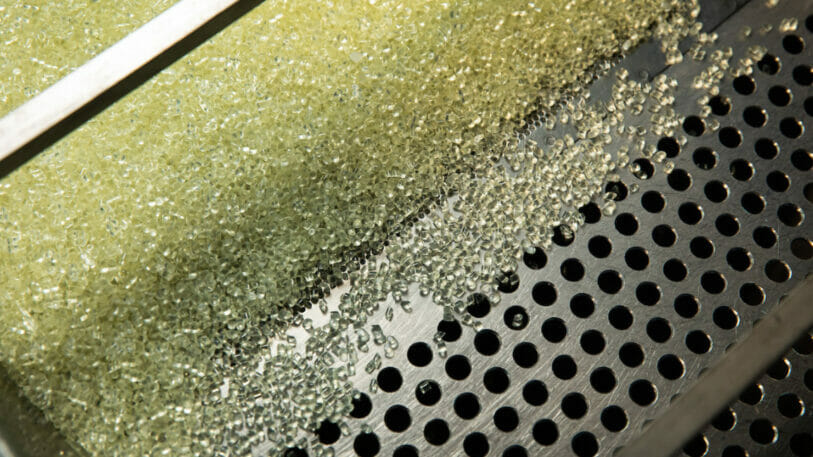

Aquapak is aiming to receive a recycling standard for its Hydropol from the CEPI. Hydropol is an innovative polymer based on Polyvinylalcohol (PVOH) and 100 per cent repulpable in standard pulping systems and can be fully recycled.

Hydropol can be successfully coated on to both paper and board, with proven gas and grease barrier properties, with additional functionality such as heat seal and increased paper sheet strength can also be imparted, making it suitable for a range of packaging uses such as bags and pouches. Aquapak has already proven that Hydropol coated paper is 100 per cent repulpable in standard pulping systems and can be fully recycled and it proven to give real improvement when set against current regulations which allow the ‘recyclable’ label to be used if there is up to 15 per cent unrecyclable material in the product. If littered Hydropol is biodegradable, compostable, as well as being non-toxic and marine-safe.

Benefits for paper packaging

The company is now targeting the new CEPI testing protocol for Hydropol, to ensure it meets the most rigorous standards. The protocol has been developed in collaboration with actors from the entire paper value chain, including specialised testing laboratories. A battery of tests were carried out over a nine month period which informed the improvements of the method and the development of three technical annexes.

The new methodology is particularly relevant to the paper packaging industry. Many paper packaging solutions already enjoy high recycling rates but are also increasingly fulfilling new functionalities. These need to be considered by brand owners aiming to reach ever higher performance in terms of circularity and sustainability for their products. Design guidelines and evaluation protocols are developed to support value chain actors in these efforts, with the end goal to make all paper packaging recyclable by 2025 and reach a recycling rate of 90 per cent by 2030. The updated CEPI harmonised recyclability test method offers a solid basis for this work and allows paper products across Europe to be tested for their recyclability in identical conditions. The new CEPI standards are based on the Italian National Recyclability Standard UNI 11743, which HydropolTMmeets.

“We welcome the introduction of these stringent tests by CEPI which are designed to harmonise recyclability validation across Europe and help boost recycling rates, and look forward to the release of the final evaluation protocol. Hydropol has already been proven to be 100 per cent recyclable under test conditions, including the Italian National Recyclability Standard on which the CEPI protocols are based, so we are confident that it will meet these new, advanced standards. Hydropol is an exciting prospect for brand owners exploring new, sustainable paper-based packaging options as a replacement for conventional polymers which are not as easily recyclable.”

Dr John Williams, Chief Technology Officer at Aquapak

Source: Aquapak

More packaging news

A contract with a handshake is valid

Managing director Tina Gerfer of Wilhelm Rasch Spezielmaschinenfabrik has modernized the company and successfully guided it through difficult times.

Asynchronous servo solutions for the packaging industry

From primary packaging to final packaging, electric drives play an important role. With a broad portfolio, Nord Drivesystems supports customers.

Label Durability

Labels offer many functions which can get lost due to label removal. PTS assesses labels and cardboard for durability and tamper evidence.

More design for recycling for cosmetics packaging

Packaging for decorative cosmetics is very special. The Forum Rezyklat calls for the recyclability of packaging to be taken into account when designing it.

Innovation Barometer 2024

According to a survey conducted by Aktionsforum Glasverpackung 2024 is set to be a highly innovative year for glass packaging.

Flexible packaging system for natural cosmetics

Sustainability is part of Weleda’s identity. IWK is also contributing to this with its new flexible packaging line for many natural cosmetic products.