At the end of November 2022, the EU Commission presented a new regulation with the Green Deal. A reduction of the growing amounts of packaging waste is a central point of the regulation. In addition, the EU defines clearer framework conditions for the use of bioplastics.

All in all, the EU has set itself three major measures with which it wants to tackle the problems. Firstly, the demand for primary raw materials is to be reduced. Secondly, the regulation provides for an increase in recycling capacities in Europe and, finally, more clarity in the use of bio-based, biodegradable and compostable plastics.

Currently, bioplastics still account for about one percent of global plastics production, but data from European Bioplastics and the Nova Institute predict that production capacity will increase by 2027. As with so many other packaging issues, it is worth taking a look at how different participants along the value chain deal with the material.

Not only black and white

On the part of consumers, the demand for alternative packaging to that made from fossil raw materials is growing steadily. Bioplastics appear to be a sustainable alternative. The packaging consists entirely or partly of renewable raw materials and biomass and is partly biodegradable or compostable.

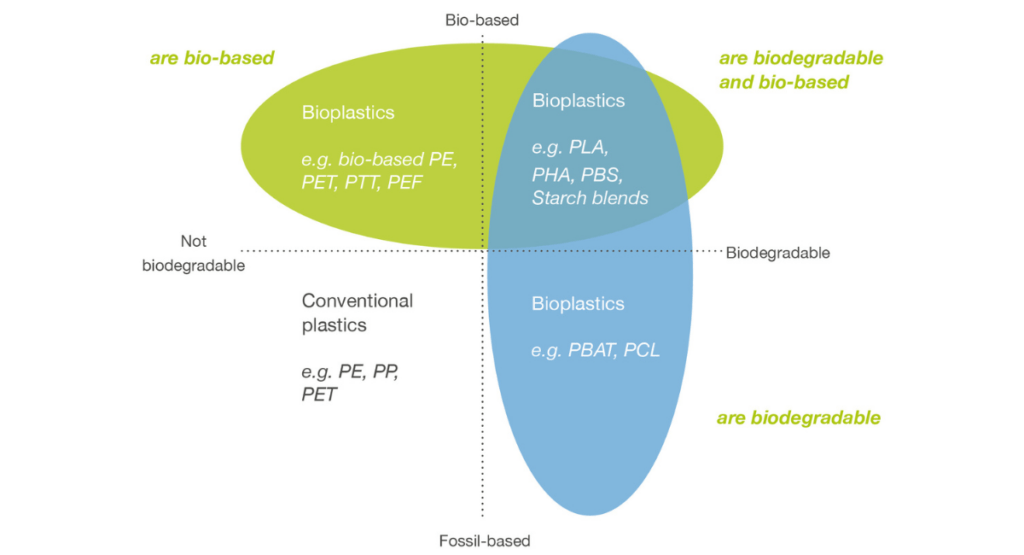

Bioplastics are polymer materials that are either made from biobased raw materials (for example, sugar cane or corn starch) and/or are biodegradable. One of these two conditions must be met for it to be a bioplastic. The material for bio-based plastics is thus obtained from biomass, whereas biodegradable plastics can also be based on petrochemical raw materials.

Even if the raw materials used do not have to be in competition with food cultivation, a difficulty becomes apparent here. The Federal Environment Agency points out that although bio-based raw materials produce less climate-impacting CO2, they are associated with the risk of higher acidification and eutrophication, depending on the cultivation method. Problematic factors such as these are currently not easily recognisable for consumers.

In addition, there is no uniform definition of the terms with which packaging made of bioplastics is labelled. For example, there is no minimum proportion of bio-based material that a packaging must have in order to be called bioplastic. Consumers cannot therefore clearly understand what kind of packaging they are buying or how they should handle it after use and when disposing of it.

Lack of clarity among consumers

The bioplastic label can therefore be misleading at the point of sale and can also influence how consumers deal with the packaging when disposing of it. A recurring concern in this context is that packaging labelled as biodegradable or compostable gives the impression that it can simply be disposed of in the environment. Fraunhofer Institut Umsicht points out here that bioplastics were not designed, and should not be thought of, to be disposed of in the environment.

Overall, bioplastics do not necessarily have to be more environmentally or climate friendly than fossil plastics. As is so often the case, this judgement stands or falls with the recycling of the materials. If bioplastics were consistently recycled, they could be environmentally friendly, according to WWF. At present, this is certainly one of the main problems, along with the often-misleading labelling. Since the volume of the materials is still low, there is no separate collection, and the packaging is sorted out and ends up in energy recovery. Some sorting plants keep the space free to establish streams for packaging made of bioplastics.

In agriculture, however, the biodegradation of mulch films already works well. The situation is different for the composting of bioplastics on an industrial scale. Plastics labelled as biodegradable should contain precise information on the environment and time period in which the packaging degrades, for the sake of clarity for consumers. Certifications such as ok compost from TÜV Austria or DIN compostable confirm the compostability of the packaging in industrial or domestic compost. Overall, the lack of information on properties, correct use and disposal can lead to problems. If it is not clearly recognisable how high the proportion of bio-based material is in the packaging, a „bio“ claim can lead to confusion.

Outlook

What is to change now? The new regulation emphasises that claims related to bioplastics must refer to measurable and accurate proportions of bio-based material in the product. The packaging should also contain precise information on the properties, proper use and disposal for consumers. Especially if the packaging is labelled as biodegradable, the environment and the time period in which the packaging decomposes should be precisely stated in weeks, months or years.

To prevent bioplastics from ending up in the environment, the EU specifies exactly which products should be packaged in industrially compostable packaging. These include tea bags, coffee pods, fruit and vegetable labels and very light plastic bags. Here again, communication is particularly important. The packaging mentioned should clearly indicate that it complies with the EU standards on bio-based plastics and their industrial composting. Overall, when using plastics, care should be taken to ensure that they have a benefit for the environment.

The protection of the environment is also a priority in the extraction of raw materials. The biomass used should come from sustainable sources, make use of waste and by-products in particular and not harm the environment. Bioplastics therefore seem to be indispensable, and therefore a sustainable and conscious handling of the materials, packaging and claims used is needed. It is not an option that a packaging ends up in the environment because it carries the label „organic“.

More packaging news

Asynchronous servo solutions for the packaging industry

Label Durability

More design for recycling for cosmetics packaging

Innovation Barometer 2024